Get interesting information about How To Make A Mold For Soft Plastic Lures, this article is specially curated for you from various reliable sources.

Fishing enthusiasts and lure makers alike understand the significance of well-crafted soft plastic lures. To create your lures, you’ll need molds that accurately reproduce the intended design and withstand the stresses of molding. This comprehensive guide will walk you through the intricate process of fabricating molds for soft plastic lures, empowering you to produce lures that mimic the natural movements and appearance of live bait.

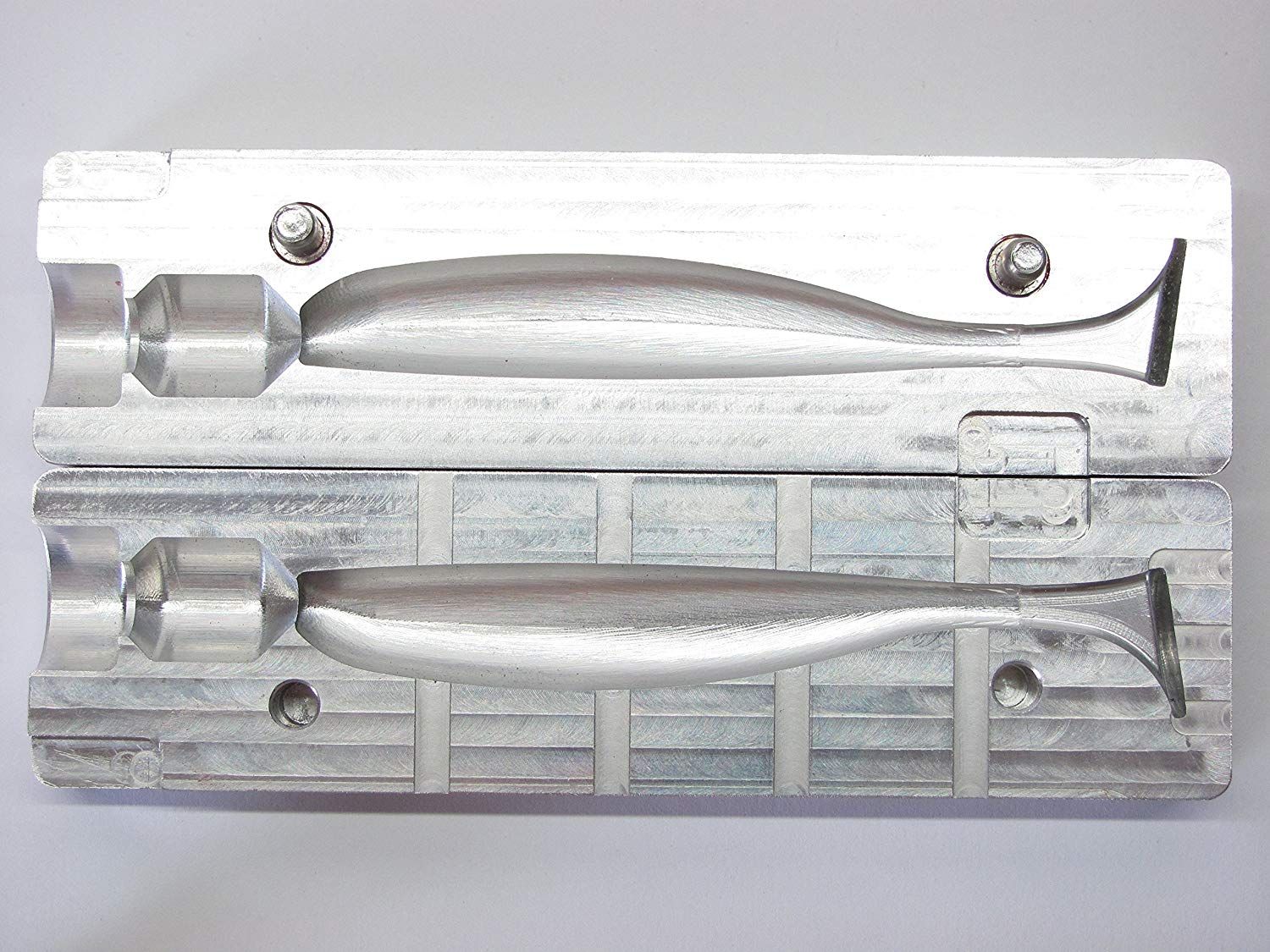

How To Make A Mold For Soft Plastic Lures

Mold Design: Precision and Accuracy

The design phase is crucial as it determines the outcome of your lures. Start by drawing the shape and features of the lure you want to create. Consider factors like body shape, fins, and scales to ensure the mold captures every detail. Transfer the design onto a flat surface, ensuring the dimensions are accurate.

Material Selection: Durability and Flexibility

The choice of material for your mold is critical. Silicone is a popular option due to its durability, flexibility, and ability to withstand high temperatures. Urethane rubber is another alternative, offering excellent strength and resistance to solvents.

Creating the Master: A Model for Perfection

The master is the original model from which the mold will be created. Carve the master from a block of wood or foam, meticulously sculpting every detail. Smooth out the surface to eliminate imperfections and create a flawless impression.

Mold Creation Process: A Two-Part Symphony

1. Preparing the Master: Apply a release agent to the master to prevent the silicone or rubber from bonding to its surface.

2. Silicone Application: Cover the master with a layer of silicone or urethane rubber, carefully removing any air bubbles.

3. Curing Time: Allow the material to cure according to the manufacturer’s instructions.

4. Second Pour: After the first layer has cured, pour a second layer over the master to create a thicker mold.

Tips and Expert Advice from the Master Molders

- Master Mold Quality: Invest in a high-quality master mold to ensure precise lures.

- Mold Thickness: Maintain a consistent mold thickness to prevent weak spots.

- Air Bubbles: Eliminate air bubbles by tapping or vibrating the mold during pouring.

- Release Agent: Apply release agent liberally to all surfaces to facilitate mold separation.

FAQ: Your Questions Answered

Q: What is the best material for soft plastic lure molds?

A: Silicone and urethane rubber are widely used for their durability and flexibility.

Q: How do I prevent the lure from sticking to the mold?

A: Apply a release agent thoroughly to the mold before pouring.

Q: Can I reuse the same mold multiple times?

A: Yes, if properly maintained, a mold can produce numerous lures.

Conclusion: The Art of Precision and Creation

Creating molds for soft plastic lures is an intricate but rewarding process that requires precision, patience, and attention to detail. By following these steps and incorporating the expert tips provided, you can master the art of mold making and produce lures that will entice even the most discerning fish.

So, are you ready to embark on this fascinating journey of lure creation? Let’s dive into the world of molds and bring your fishing aspirations to life!

How To Make A Mold For Soft Plastic Lures

Image: www.youtube.com

You have read an article about How To Make A Mold For Soft Plastic Lures. We express our gratitude for your visit, and we hope this article is beneficial for you.