Imagine driving along the highway, enjoying the smoothness of your car’s ride, when suddenly you hear a disconcerting noise. A rattling, grinding sound fills the cabin, growing louder with every mile you drive. Panic sets in as you realize the dreaded: you have a spun bearing. Fear not, automotive aficionado! In this comprehensive guide, we will delve into the intricacies of spun bearings, their causes, consequences, and the ultimate solution—how to fix them.

Image: www.thesamba.com

Defining a Spun Bearing and Its Critical Impact

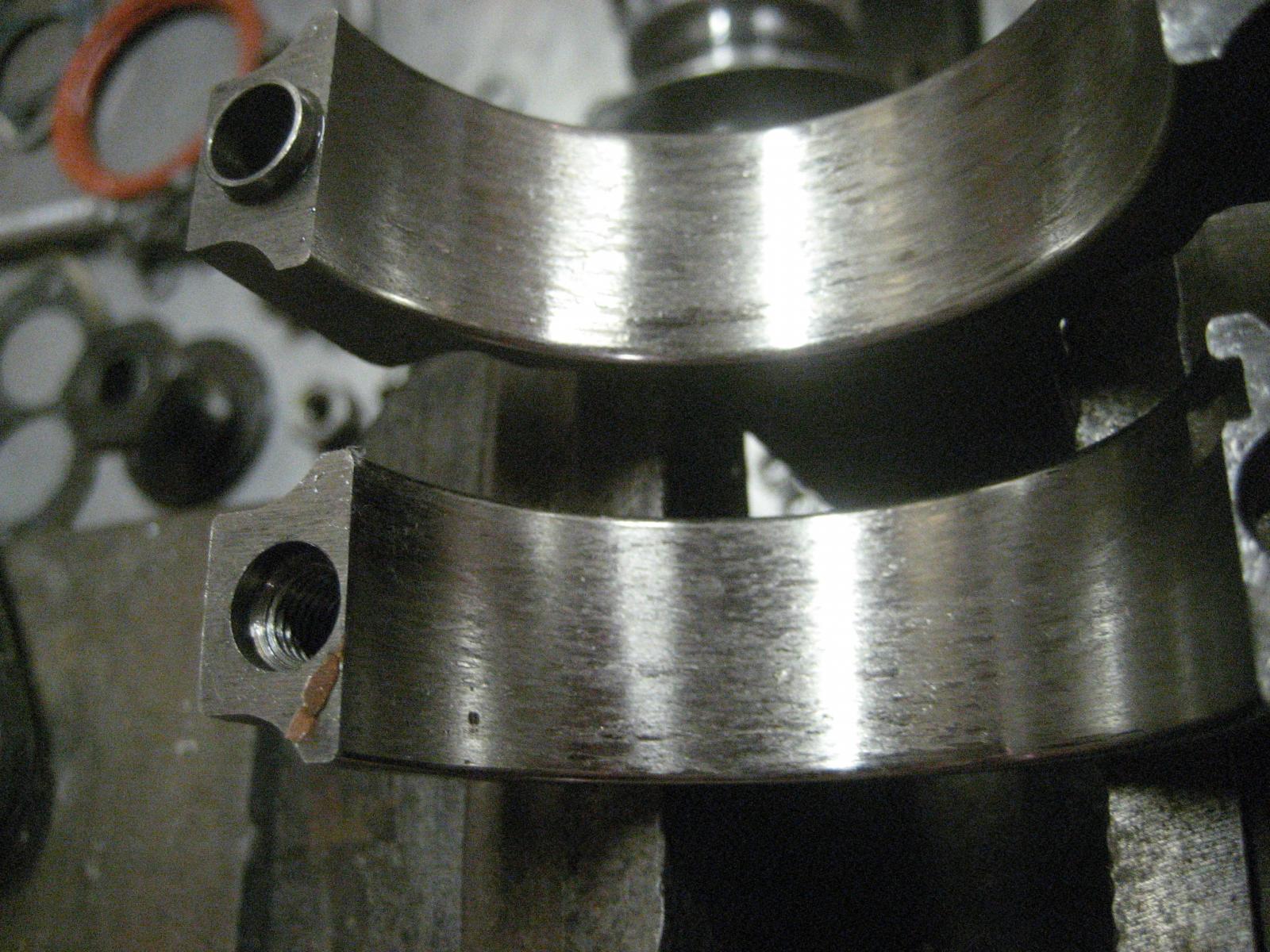

A spun bearing is a severe engine failure that occurs when the bearing lining material between the crankshaft and connecting rod becomes detached, allowing metal-on-metal contact. This catastrophic event can lead to extensive damage to the engine’s internal components, resulting in costly repairs or even engine replacement. Understanding the significance of spun bearings is paramount for any automotive enthusiast seeking to extend the life and performance of their beloved machines.

Uncovering the Causes of Spun Bearings: A Journey of Prevention

To effectively address the issue of spun bearings, it is essential to delve into the underlying causes of this dreaded engine failure. Numerous factors can contribute to the spinning of a bearing, including:

- Insufficient Lubrication: Inadequate oil supply or pressure can lead to a breakdown of the lubrication film between the bearing and the crankshaft, resulting in metal-on-metal contact.

- Overheating: Extreme engine temperatures can weaken and degrade the bearing material, making it more susceptible to spinning.

- Excessive Load: Putting too much stress on the engine by towing heavy loads or frequently operating at high RPMs can overwork the bearings, causing them to fail.

- Bearing Tolerance Problems: Improper bearing clearance or incorrect bearing sizing can result in excessive play, leading to bearing damage and spinning.

- Debris or Contaminants: The presence of metal shavings, dirt, or other foreign objects in the oil can act as abrasives, accelerating bearing wear and failure.

By understanding these causes, automotive enthusiasts can adopt proactive maintenance strategies to prevent spun bearings. Regular oil changes, proper engine cooling, and avoiding excessive engine load are crucial steps towards ensuring the longevity and reliability of your car’s internal combustion engine.

Diagnosing Spun Bearings: Identifying the Telltale Signs

Recognizing the early warning signs of a spun bearing is the key to minimizing engine damage and preventing costly repairs. Listen attentively for unusual noises emanating from the engine, especially during acceleration or under load. A rattling or knocking sound that increases in intensity as the engine speed rises could indicate a spun bearing. Other symptoms to watch out for include:

- Oil Pressure Drop: A sudden drop in oil pressure can be indicative of a spun bearing, as the damaged bearing allows oil to escape.

- Metal Particles in Oil: If the spun bearing has caused metal-on-metal contact, tiny metal particles may be found suspended in the oil during an oil change.

- Engine Overheating: A spun bearing can generate excessive friction, leading to increased engine temperatures and potential overheating.

If you suspect a spun bearing, it is essential to consult a qualified mechanic immediately. Delaying repairs can result in catastrophic engine damage, requiring extensive and expensive overhauls.

Image: www.youtube.com

Repairing Spun Bearings: A Step-by-Step Guide for Experienced Mechanics

Fixing a spun bearing is a complex and labor-intensive process that requires specialized knowledge and tools. It involves disassembling the engine, removing the damaged crankshaft, and replacing or repairing the spun bearing. The following steps provide a brief overview of the repair process:

- Engine Disassembly: Carefully disassemble the engine, following the manufacturer’s service manual, to access the crankshaft and connecting rod.

- Removing the Crankshaft: Disconnect the crankshaft from the connecting rods, flywheel, and other components, and carefully remove it from the engine block.

- Assessing Crankshaft Damage: Inspect the crankshaft for damage caused by the spun bearing, such as scratches, gouges, or deformation. If necessary, the crankshaft may need to be reground or replaced to ensure proper bearing operation.

- Replacing the Spun Bearing: Remove the old bearing from the connecting rod and install a new one, ensuring correct alignment and preload as specified by the manufacturer.

- Reassembling the Engine: Reassemble the engine in reverse order of disassembly, ensuring proper torque specifications and correct installation of all components.

Attempting to repair a spun bearing without proper expertise and equipment can lead to further engine damage, potentially resulting in a more costly repair or even engine replacement. It is highly recommended to entrust this complex task to a qualified mechanic with extensive experience in engine repair.

How To Fix Spun Bearing

Mitigating Future Spun Bearings: Lessons Learned for Automotive Enthusiasts

To prevent the recurrence of spun bearings in the future, it is imperative to adopt proactive maintenance practices and address underlying issues that may contribute to bearing failure. Consider the following preventive measures:

- Regular Oil Changes and Oil Filter Replacement: Maintain a consistent oil change schedule to ensure a clean oil supply and remove contaminants that could damage bearings. Use high-quality oil that meets the manufacturer’s specifications.

- Proper Engine Cooling: Ensure the engine cooling system is functioning correctly to prevent overheating and bearing damage. Inspect and replace coolant regularly, and maintain a properly functioning thermostat and water pump.

- Avoid Excessive Engine Load: Refrain from towing excessively heavy loads or operating the engine at high RPMs for prolonged periods. Allow the engine to cool down gradually after heavy loads or high-speed driving.

- Professional Engine Inspection and Repair: Schedule regular engine inspections with a qualified mechanic to identify and address potential issues before they lead to bearing failures.